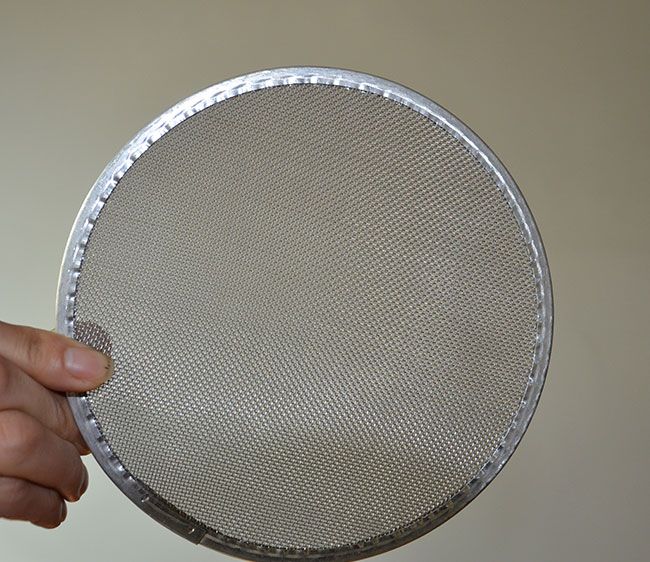

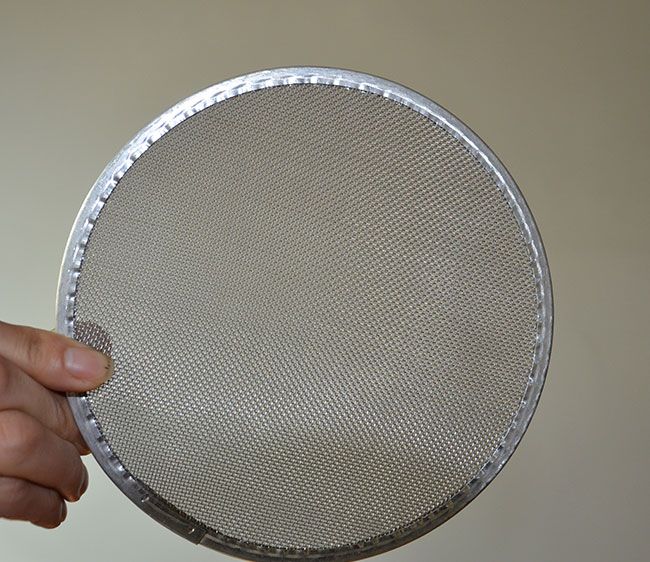

edging filter

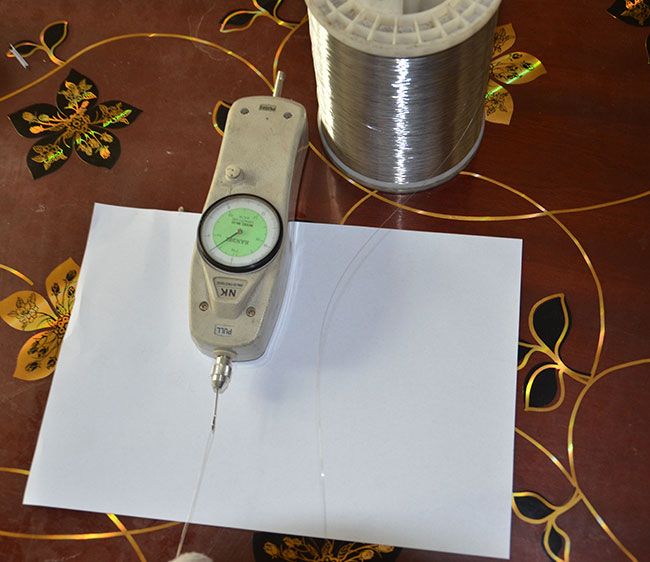

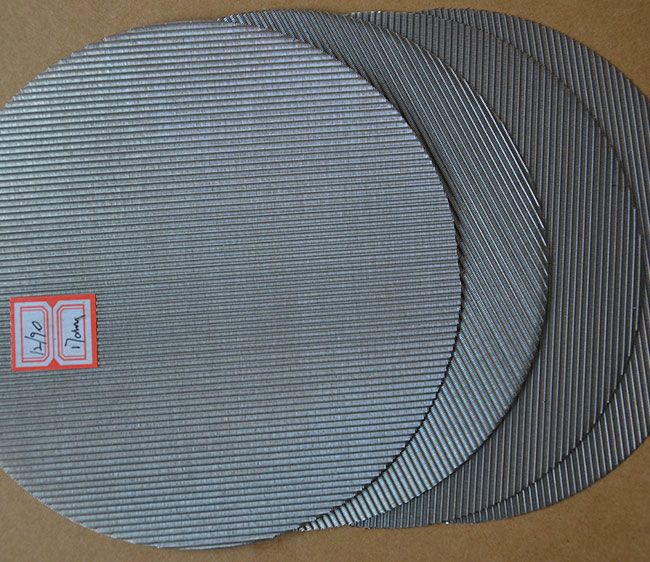

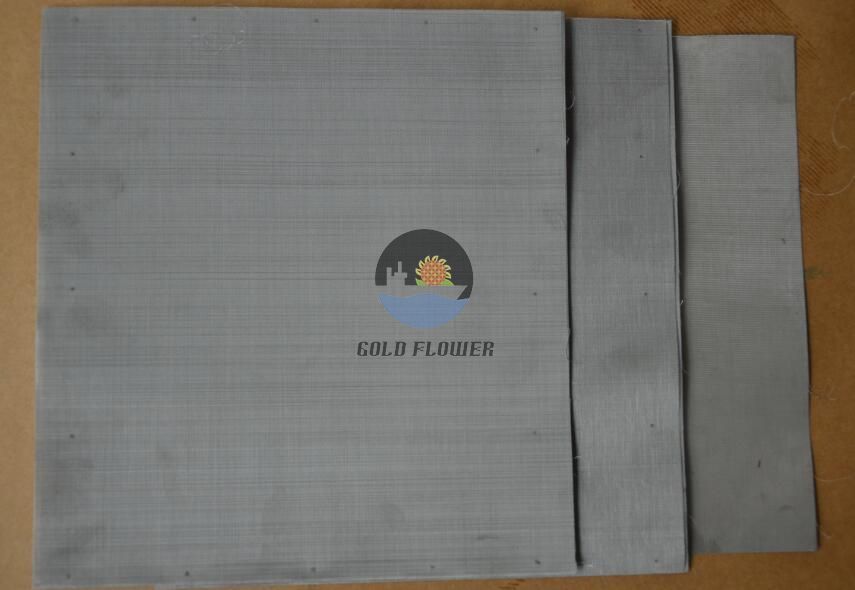

1. Product name:filter piece.

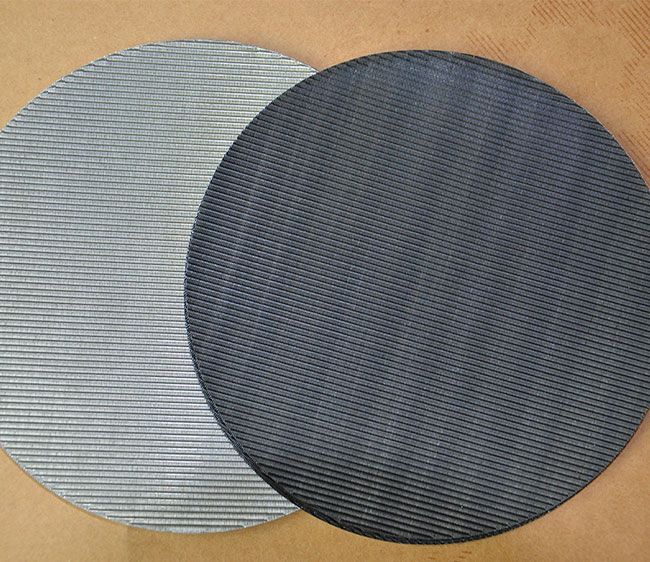

2 Material: stainless steel Aisi316,316L,304L,304,black wire.

3. Form: circle,square and etc.

4. Size: 75mm,133mm,170mm,230mm,255mm,302mm,or with inquiry.

5. Use: for filter and etc.

Filtering Mesh Packs: Enhancing Efficiency in Filtration Systems

Introduction

When it comes to efficient filtration systems, the quality and performance of the filter media play a crucial role. Filtering mesh packs are a popular choice for various industrial applications due to their exceptional filtering capabilities. In this comprehensive guide, we will delve into the world of filtering mesh packs, exploring their features, benefits, and applications. Whether you are a professional in the filtration industry or simply interested in learning more, this article will provide you with valuable insights.

Filter disc has better performance in damper environment or where paper filter discs couldn't supply sufficient rigidity and strength. It also features outstanding durability and suitable ability. Therefore it not only can withstand temperature range in excess of 500 F and high pressure but also can be manufactured by spot welding and perforating. What's more, filter discs can be designed to be compatible with most caustic fluids and they are cleanable and reusable. Therefore, compared with paper and cloth filter discs, metal filter discs can offer a long service life.

What are Filtering Mesh Packs?

Filtering mesh packs are specialized filtration media consisting of a mesh material that is tightly woven together to form a porous structure. These packs are designed to efficiently remove impurities and contaminants from liquids or gases, ensuring a clean and purified output. The mesh size, material composition, and construction of these packs can be tailored to suit specific filtration requirements.

The Importance of Filtering Mesh Packs

Proper filtration is essential in a wide range of industries, including chemical processing, oil and gas, water treatment, pharmaceuticals, and food and beverage production. Filtering mesh packs offer several key advantages that make them an ideal choice for these applications:

1. High Filtration Efficiency: The tightly woven mesh structure of filtering mesh packs ensures excellent filtration efficiency, effectively capturing particles of various sizes.

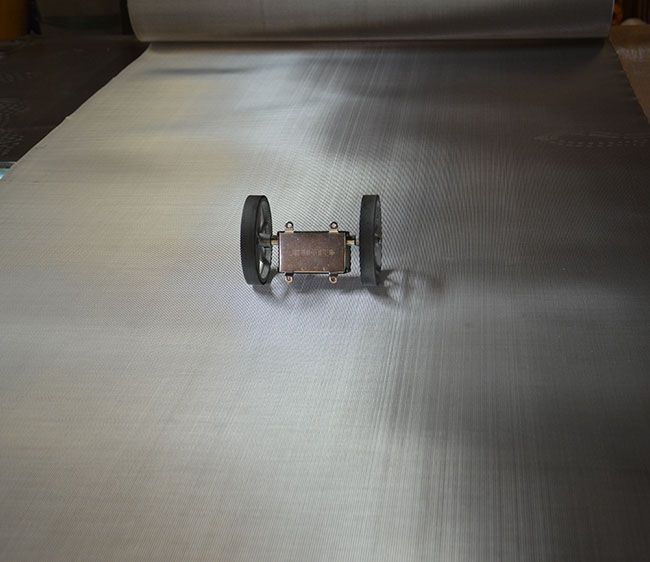

2. Consistent Performance: Filtering mesh packs provide consistent and reliable filtration performance over their lifespan, maintaining the desired level of filtration even under demanding conditions.

3. Customizability: With filtering mesh packs, it is possible to customize the mesh size, material, and overall design to meet specific filtration requirements, allowing for optimal performance in various applications.

4. Longevity: Filtering mesh packs are durable and long-lasting, offering extended service life and reducing the need for frequent replacements, resulting in cost savings.

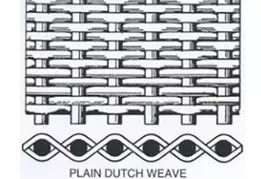

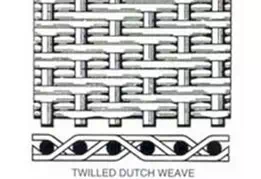

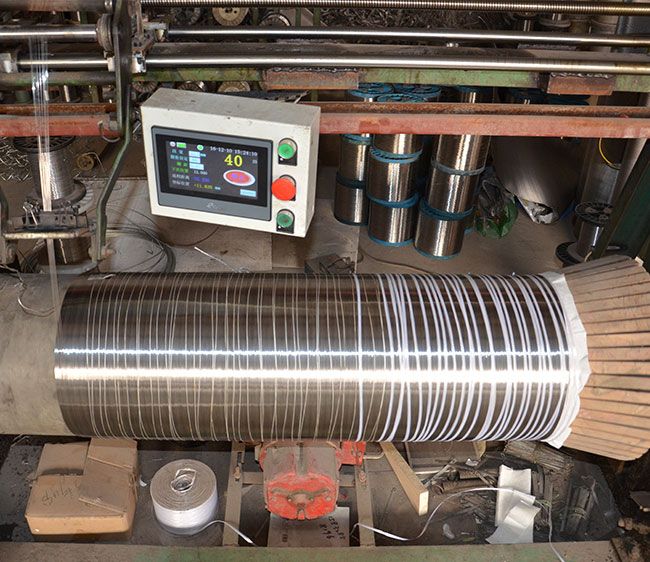

Woven Type

Plain wave,twill weave and dutch weave.

Application

The filter has been widely used in transfomer oil, turbine oil, hydraulic oil, aviation kerosene, petrolem, chemical, power plant, coal carbon, mining, pharmaceutical, food and engineering industries.

Features

1. High Strength,extreme mechanical strength and pressure tolerance,can be machined,welded and assembled.

2.Heat resistant: can be continuously used in temperature ranging from -200°C to 600°C and filtering in acid and alkali conditions.

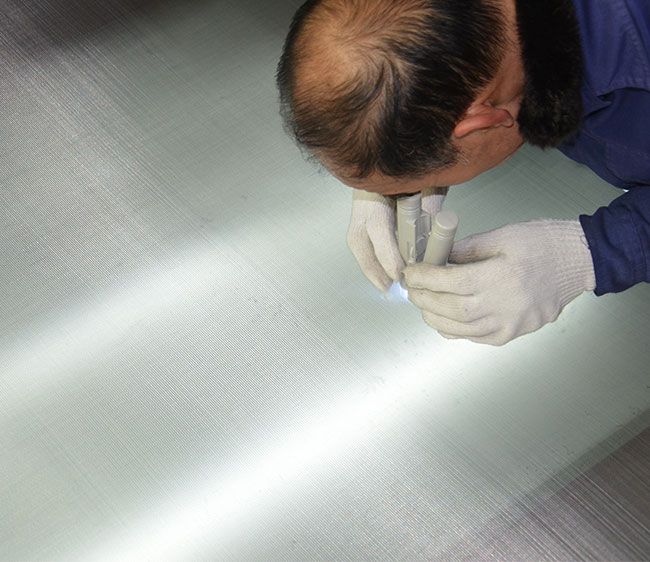

3.High Precision:Consistent filter property in media grades, without apertures changing during operation

4.Cleanable:backwash and clean easily,can be reused with longer service span,and can be cleaned by means of ways,such as backstream,filtration liquid,ultrasonic,dissolution and baking.

We look forward to working with you!

ANPING GOLDFLOWER WIRE MESH FACTORY is your best choice! Filtering mesh packs are indispensable tools for achieving efficient and reliable filtration in various industries. Their high filtration efficiency, customizability, and durability make them a preferred choice for professionals seeking optimal filtration performance. By understanding the applications, benefits, and considerations associated with filtering mesh packs, you can make informed decisions in selecting the right filtration media for your specific requirements. If you are interested in our products, please contact us as soon as possible.