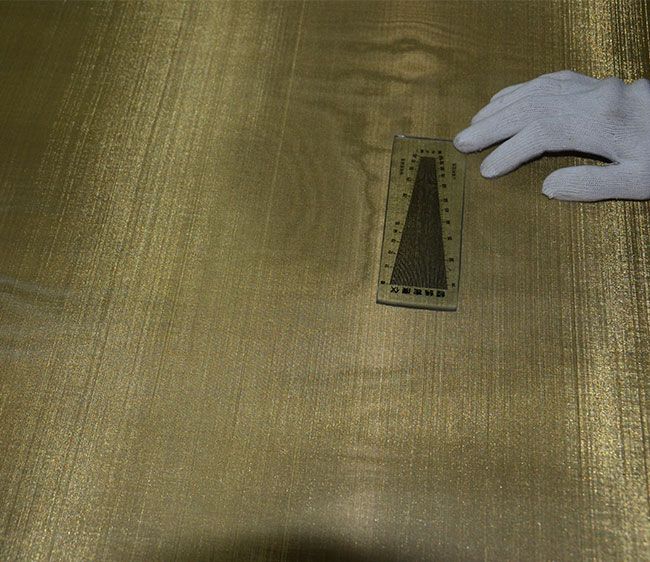

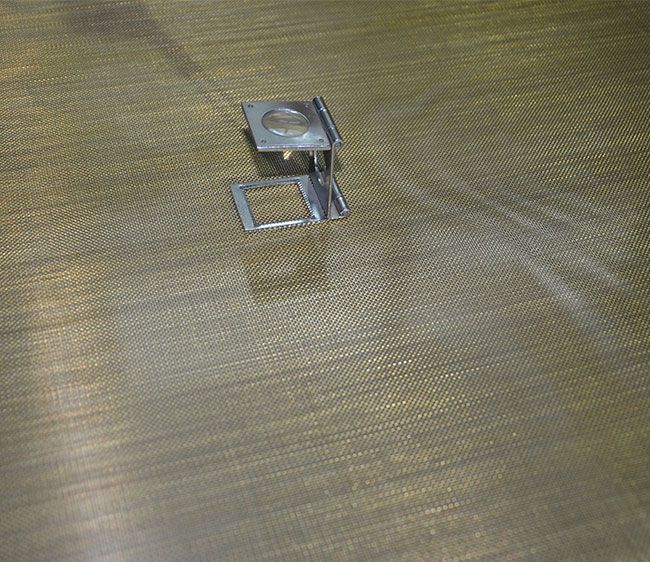

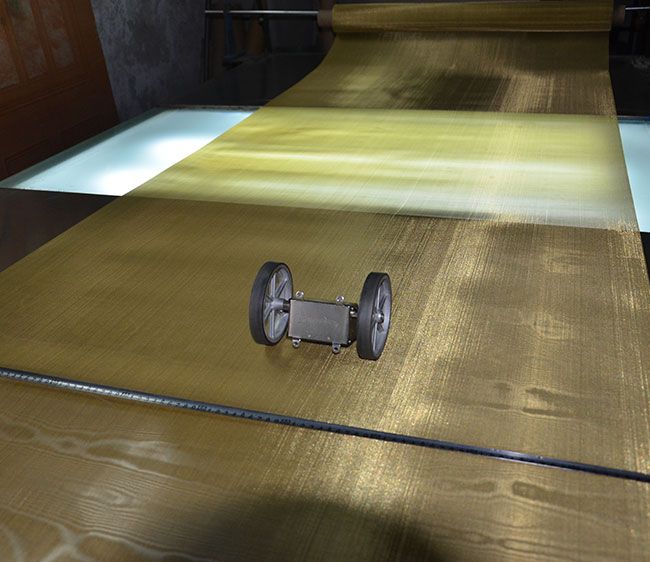

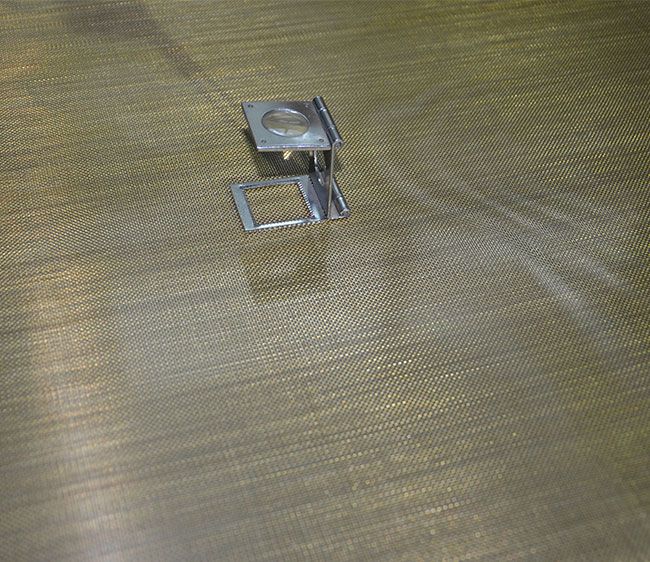

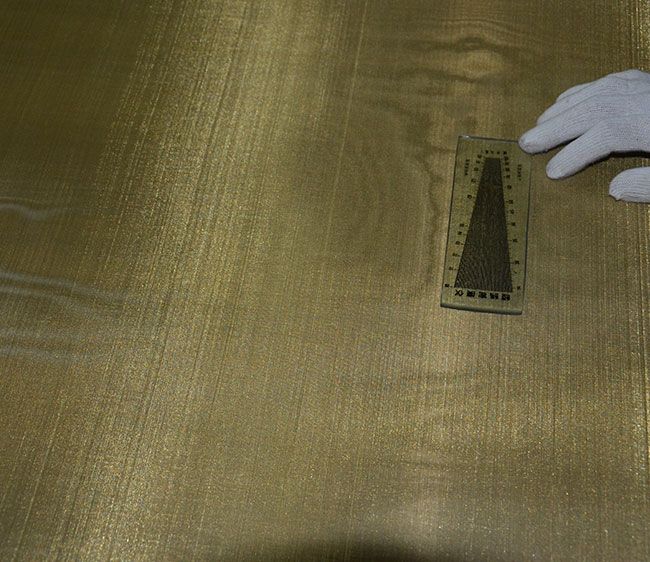

Non magnetic Copper Mesh

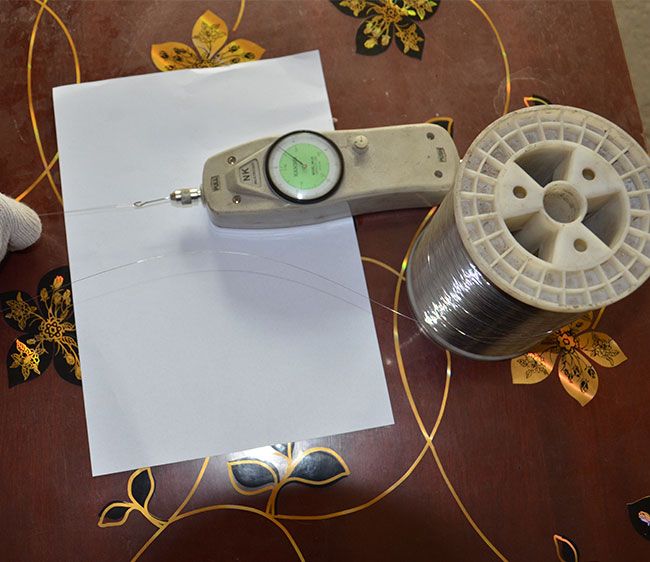

Material: brass wire,copper wire.

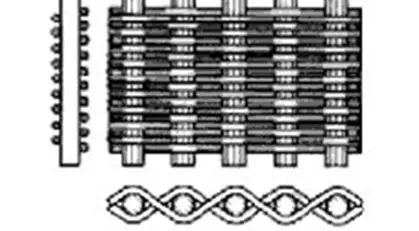

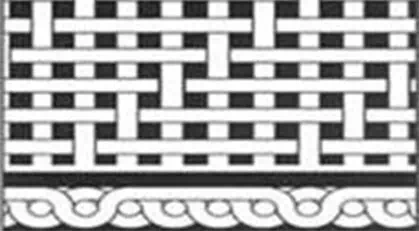

Weave: plain dutch,twilled dutch,reverse ,five heddle weave.

Characteristics: acid resisting,alkali resisting,heat resisting and wear resisting.

Application: used for liquid ,industries of mining,oil, chemical, food, phamaceutical, machine making, scientific research,aviation,etc.

Features of Non magnetic copper mesh:has excellent abrasion resistance, corrosion-resisting, lower electric conductivity as compared with copper.

Features of Non magnetic copper mesh: offers excellent electrical and thermal conductivity, it is non-magnetic, anti-sparking and is resistance to atmospheric corrosion, salt air and brine. Copper applications are limited due to its low tensile strength, poor resistance to abrasion and common acids.

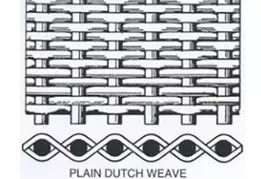

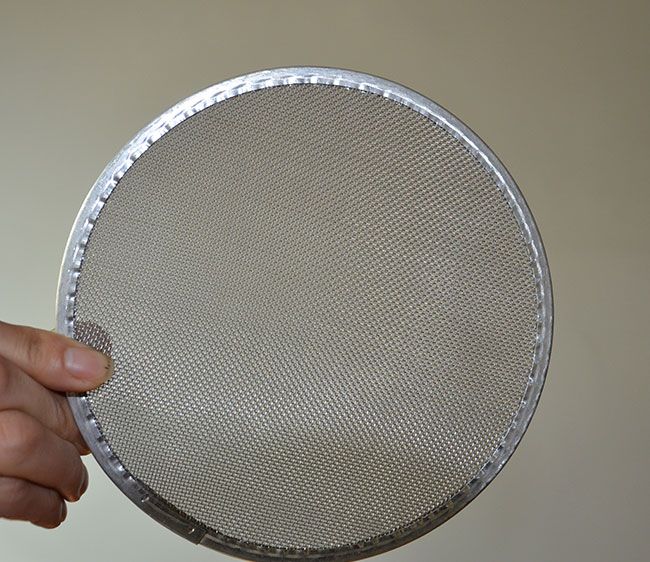

Plain weave:

Each warp wire and each weft wire passes over and under the next adjacent wire.

Plain dutch weave woven wire cloth has two sizes of wire diameter. The weft wires has thinner wire diameter, which is woven tightly together to provide a tight mesh for filtering. The warp wires has coarser wire diameter, which provides strength to the woven wire cloth.

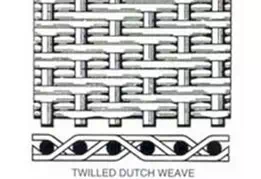

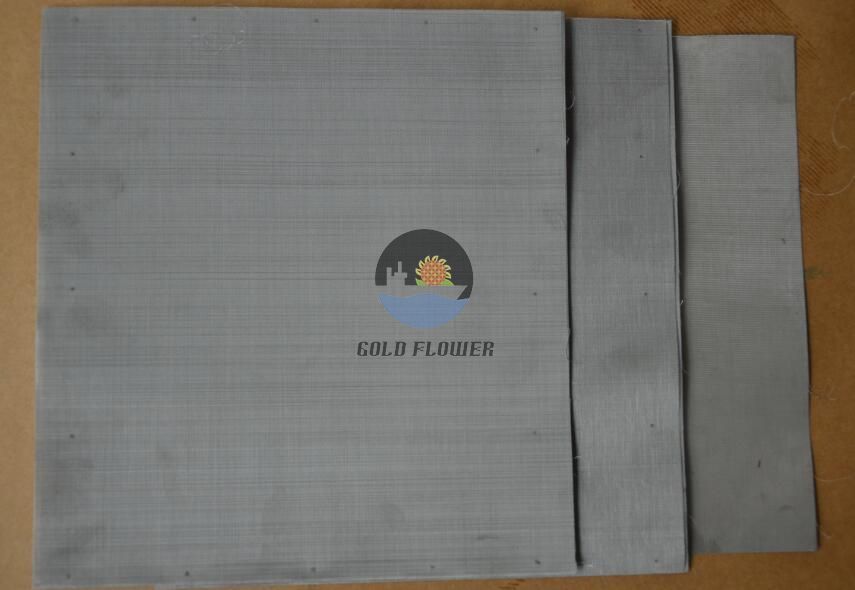

Twill dutch weave

It is the extension of the twill weave. Each warp wire and each weft wire passes over and under the next two adjacent complementary wires, which is similar as twill weave. The wire diameter of warp wire is larger than weft wire. The mesh count in the weft direction is greater than the warp direction. Dutch twill weave enables the weft wires to be woven more densely and much smaller aperture sizes can be achieved.

Twill dutch weave is capable of supporting greater loads than the dutch weave. It has finer openings than the twilled weave. It is used for filtering heavy materials.

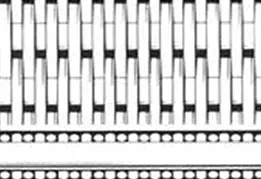

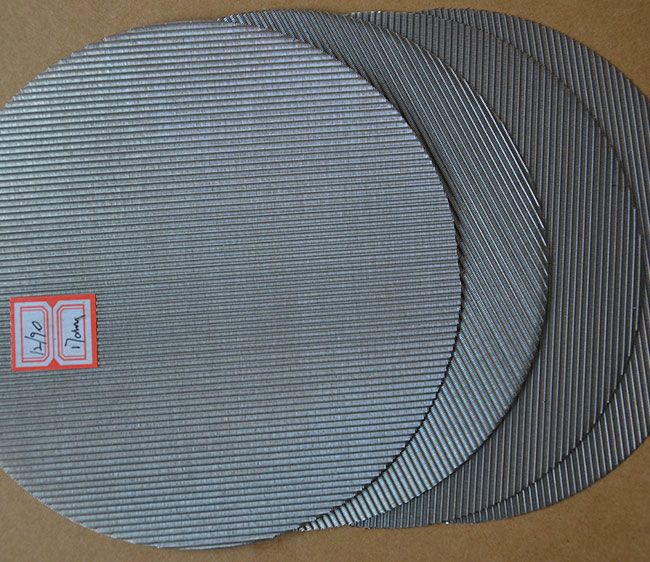

Reverse dutch weave woven wire cloth

Reverse dutch weave woven wire cloth has finer wire diameter in warp wire and coarser wire diameter in weft wire. and the mesh count in the warp wire is larger than the weft wire.

| Mesh/inch | Wire diameter/SWG | Wire diameter/mm |

| 5 | 25 | 0.508 |

| 6 | 22 | 0.711 |

| 10 | 25 | 0.508 |

| 12 | 26 | 0.457 |

| 14 | 27 | 0.417 |

| 16 | 29 | 0.345 |

| 20 | 30 | 0.315 |

| 22 | 30 | 0.315 |

| 26 | 31 | 0.295 |

| 28 | 31 | 0.295 |

| 32 | 33 | 0.254 |

| 34 | 34 | 0.234 |

| 36 | 34 | 0.234 |

| 38 | 35 | 0.213 |

| 44 | 37 | 0.173 |

| 50 | 37 | 0.173 |

| 60 | 37 | 0.173 |

| 90 | 41 | 0.112 |

| 100 | 42 | 0.102 |

| 120 | 43 | 0.091 |

| 150 | 46 | 0.061 |

| 160 | 46 | 0.061 |

| 200 | 47 | 0.051 |

| 300 | 48 | 0.041 |

| 350 | 49 | 0.033 |