Architectural wire mesh is a type of metal fabric used in building design and construction to create unique, functional, and aesthetically pleasing structures. It is made from a variety of materials such as stainless steel, aluminum, brass, and copper, and can be woven into various patterns, shapes, and sizes.

Here is the ultimate guide to architectural wire mesh:

Types of Architectural Wire Mesh

There are several types of architectural wire mesh that vary based on the materials used, the weaving patterns, and the intended use. Some of the most common types include:

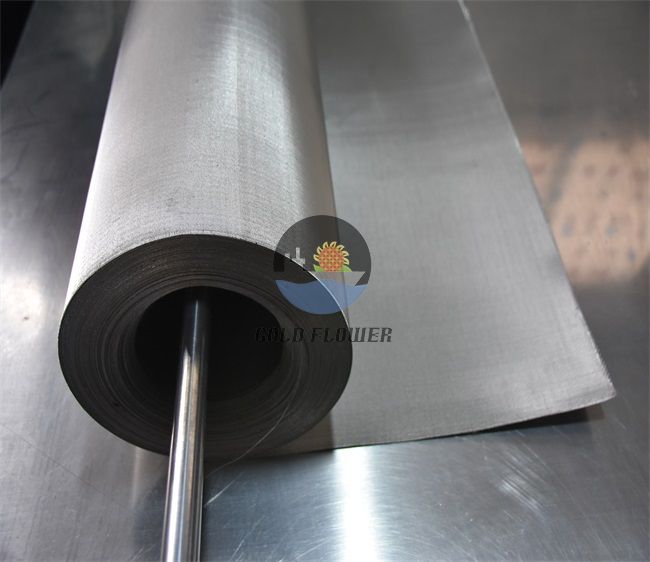

Woven wire mesh: This is the most common type of architectural wire mesh, and it is made by interlocking wires in a crisscross pattern. Woven wire mesh can be used for facades, interior partitions, and decorative accents.

Expanded metal mesh: This type of mesh is made by stretching a metal sheet to create diamond-shaped openings. It is often used for security screens, fences, and grilles.

Perforated metal mesh: Perforated metal mesh is made by punching holes into a metal sheet. It is commonly used for sunshades, acoustic panels, and ventilation screens.

Welded wire mesh: This type of mesh is made by welding wires together to create a grid pattern. It is commonly used for industrial applications, such as safety barriers and machine guards.

Decorative Mesh Screen Curtain

Materials Used in Architectural Wire Mesh

Architectural wire mesh can be made from a variety of materials, including stainless steel, aluminum, brass, copper, and titanium. The material used will depend on the intended use of the mesh, the desired aesthetic, and the level of durability required. Stainless steel is a popular choice for its strength and durability, while aluminum is lightweight and easy to work with.

Weaving Patterns

Architectural wire mesh can be woven into a variety of patterns, each with its own unique aesthetic and functional properties. Some of the most common weaving patterns include:

Plain weave: This is the simplest and most common weaving pattern, in which the wires are woven in an over-under pattern.

Twilled weave: This pattern creates a diagonal pattern by weaving the wires over two and under two.

Dutch weave: This pattern uses a thicker wire in the warp (vertical) direction and a thinner wire in the weft (horizontal) direction to create a tighter mesh with a smoother surface.

Applications of Architectural Wire Mesh

Architectural wire mesh can be used in a wide range of applications, including:

Façade cladding: Mesh can be used to create a visually striking façade that can enhance the aesthetics of the building.

Interior partitions: Mesh can be used to create unique interior partitions that provide privacy while still allowing light to pass through.

Sunshades and louvers: Mesh can be used to create sunshades and louvers that provide shade and privacy while still allowing airflow.

Ceilings and acoustic panels: Mesh can be used to create decorative ceilings and acoustic panels that absorb sound and improve acoustics.

Balustrades and handrails: Mesh can be used to create decorative balustrades and handrails that enhance the aesthetics of the building.

Installation and Maintenance

Architectural wire mesh is typically installed using a variety of methods, including tensioning systems, frames, and brackets. It is important to ensure that the mesh is properly tensioned to prevent sagging and ensure its long-term durability.

Maintenance of architectural wire mesh is relatively simple and usually involves regular cleaning to remove dirt and debris. Stainless steel mesh can be cleaned using mild detergent and water, while aluminum mesh can be cleaned using a mixture of vinegar and water.