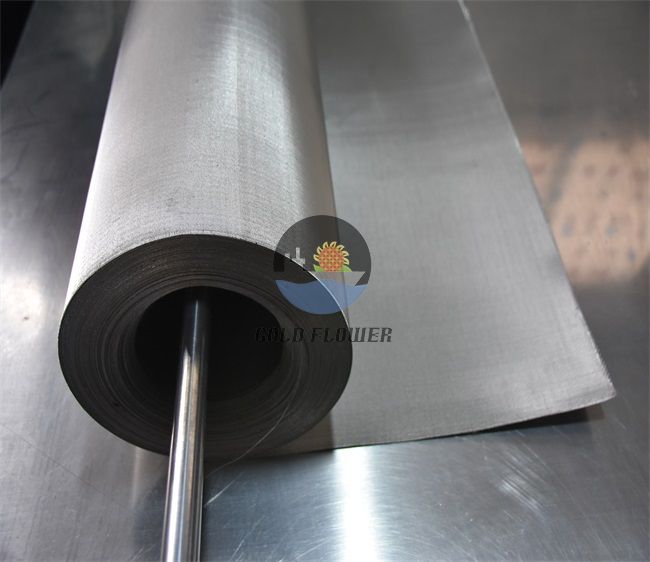

With many different water treatment products and processes on the market, including bag filtration, depth filtration and surface filtration, the use of filter mesh is becoming more common and manufacturers are able to design highly specific models to meet stringent applications and specific needs in industries such as medical, beverage, food, engineering and chemical processing.

But when you use cartridges in industrial grade systems, how can you make your cartridges last longer? The trick is to first select the right cartridge and treatment system for your application to protect the ultimately more expensive cartridge with lower cost coarse filtration, and secondly to carefully monitor its use and fully maintain the system to ensure full efficiency and compliance with the instructions for use. Let's take a closer look.

Which filter cartridge is it?

Water filters and treatment technologies are now so advanced that they can be chosen to provide accurate results of up to 99.99% reduction of certain contaminants if they are selected, applied and managed correctly in the process.

It is critical that a water treatment specialist conducts a thorough diagnosis of your needs and operation before making recommendations regarding the correct type of process and cartridge to provide the results you need.

Often, cartridges are used in conjunction with other water treatment and filtration processes and need to be installed as a whole in a larger system. Your technician will review the following inputs.

Processes used

From removing dirt from borehole water to removing bacteria from water used in food manufacturing, the broader water treatment and filtration process needs to be considered along with the necessary outputs and results.

Temperature

Cartridges are designed to withstand temperatures up to steam sterilization levels (for example, where bacteria and viruses are removed). Each cartridge will be designed to operate within a specific temperature range and will work optimally in maintaining this temperature range.

Liquid Flow

In addition, some cartridges are designed for high liquid flow rates, while others are designed for low flow rates. The right choice will again maximize the operating life and the integrity of the internal delivery mechanism.

Micron Grades

From Cryptosporidium, Giardia spores and yeast cells to granular sand and paint residue, each filter must be carefully matched to the material to be removed from the water.

Incorrect selection naturally means that the results of the process will suffer and that cartridges will clog more quickly if they are overloaded.

Monitoring and Maintenance

Once the correct cartridge has been selected, it must be used in strict accordance with the user guide provided.

Each cartridge will be individually labeled and boxed for easy installation, and the maintenance team (whether in-house or outsourced) must regularly check the operation of the cleaning and filtration system to ensure that it is optimized and adjusted when needed, allowing for measurement of factors such as pressure drop, flow rate and fluid quality.

Again, this maintains the maximum working life and efficiency of the cartridge and other components, just as the smooth driving of a car will maintain the life of its engine.

Regular maintenance, cleaning, inspection and replacement of components in the broader water treatment system is also essential to ensure that pressure is not applied excessively to some elements of the system and that others begin to fail.

The field of water treatment and filtration can be complex, especially in industrial applications, and this specialized field requires knowledge, experience, technology and the right service support to get it right.

However, when best practice processes are followed, equipment life can be maintained at 100-piece efficiency and the overall integrity of the system will be preserved for optimal treatment results.

Please contact GOLDFLOWER to get the quote.