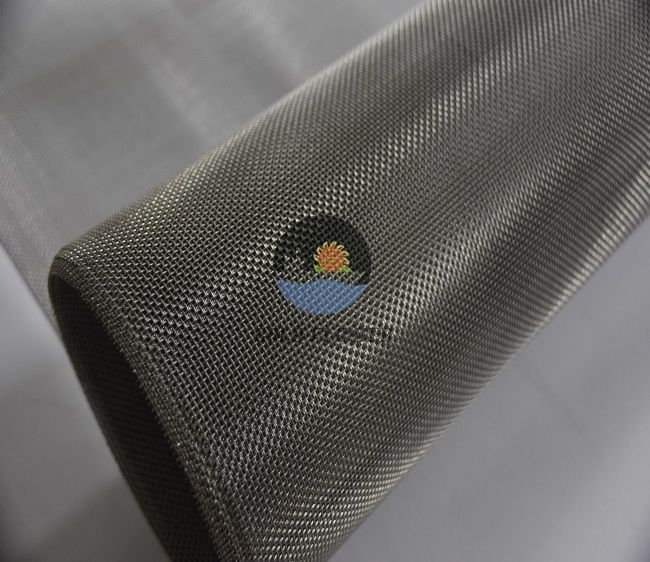

Wire Mesh Screen

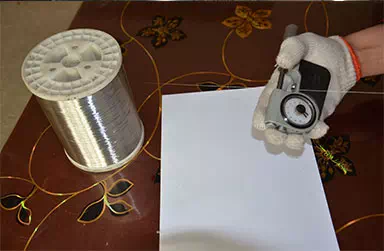

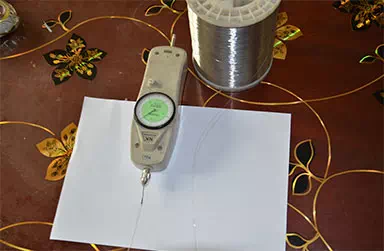

Materials: SUS302、304、316、304L、316L stainless steel wire

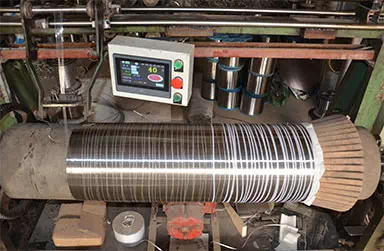

Weaving: Plain, Twill, Dutch.

Features: Acid resistant, alkali resistant, heat resistant, corrosion resistant.

Uses: Used in mine, petroleum, chemical, food, medicine, machine making, etc.

Our factory is specialized in various of wire mesh,we have professional production and service.

Stainless steel wire mesh is our superior product,we have exported it to many countries in the world.The weaving is determined according to our customers’ specific requirements, such as the material, the wire diameter, the size of the mesh , width and length.

Plain weave:

Each warp wire crosses alternately above and below each weft wire. Warp and weft wires generally have the same diameter.

Twill Weave:

The wires of the weft and the warp intercross two above and two below, inverting the intersections of the warp wire at an established distance and obtaining a rigid, stable and robust type of wire mesh fabric.

Dutch Twilled Weaving:

The wires of the weft and the warp intercross two above with a larger weft wire than the warp.

Such kind of wire mesh allows a greater difference between the diameter and the number of weft and warp wire.

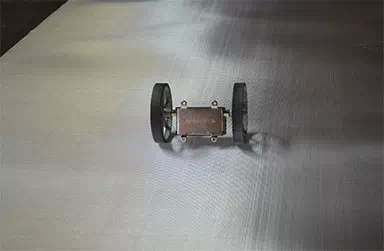

Feature of wire mesh screen

· Corrosion resistance.

· Anti-acid and alkali resistance

· Anti-high temperture.

· Good filter performance.

· Long using life

Application of wire mesh screen

· In acid, alkali environment conditions sieving and filtering.

· Petroleum industry as mud mesh,.

· Chemical fiber industry as screen mesh.

| No. | Hole size, мм | Wire diameter, мм |

| 04 | 0,40 | 0,20; 0,25 |

| 045 | 0,45 | 0,20; 0,25 |

| 05 | 0,50 | 0,20; 0,25; 0,30 |

| 055 | 0,55 | 0,22; 0,28 |

| 063 | 0,63 | 0,25; 0,32 |

| 07 | 0,70 | 0,22; 0,28; 0,32 |

| 08 | 0,80 | 0,25; 0,32 |

| 09 | 0,90 | 0,22; 0,36 |

| 1 | 1,00 | 0,25; 0,32; 0,40 |

| 1,1 | 1,10 | 0,28; 0,36 |

| 1,2 | 1,20 | 0,32; 0,40 |

| 1,4 | 1,40 | 0,36; 0,45; 0,65 |

| 1,6 | 1,60 | 0,32; 0,40 |

| 1,8 | 1,80 | 0,45; 0,05; 0,70 |

| 2 | 2,00 | 0,40; 0,50; 0,60; 1,00; 1,20 |

| 2,5 | 2,50 | 0,40; 0,50; 0,60 |

| 2,8 | 2,80 | 0,45; 0,90 |

| 3,2 | 3,20 | 0,50; 0,80; 1,20 |

| 3,5 | 3,50 | 0,70; 0,90; 1,00 |

| 4 | 4,00 | 0,60; 1,00; 1,20 |

| 4,5 | 4,50 | 0,70; 0,90; 1,80 |

| 5 | 5,00 | 0,70;1,20; 1,60; 2,00 |

| 6 | 6,00 | 0,70; 1,20; 2,00 |

| 7 | 7,00 | 0,70; 1,20; 1,80 |

| 8 | 8,00 | 0,70; 1,20; |

| 9 | 9,00 | 1,60; 2,00 1,00; 2,00; |

| 10 | 10,00 | 2,20 |

| 12 | 12,00 | 1,00; 2,00; 1,00; 1,20; |

| 14 | 14,00 | 2,00; 1,00; 1,40; 2,00 |

| 16 | 16,00 | 1,60; 2,50 |

| 18 | 18,00 | 1,80; 2,50 1,60; 2,00; |

| 20 | 20,00 | 2,50 |